By Stephen Lane

At IPS, Stephen Lane is tasked with working directly with clients and internally with the team to develop simulation models to support sites worldwide

Manufacturing movement insights:

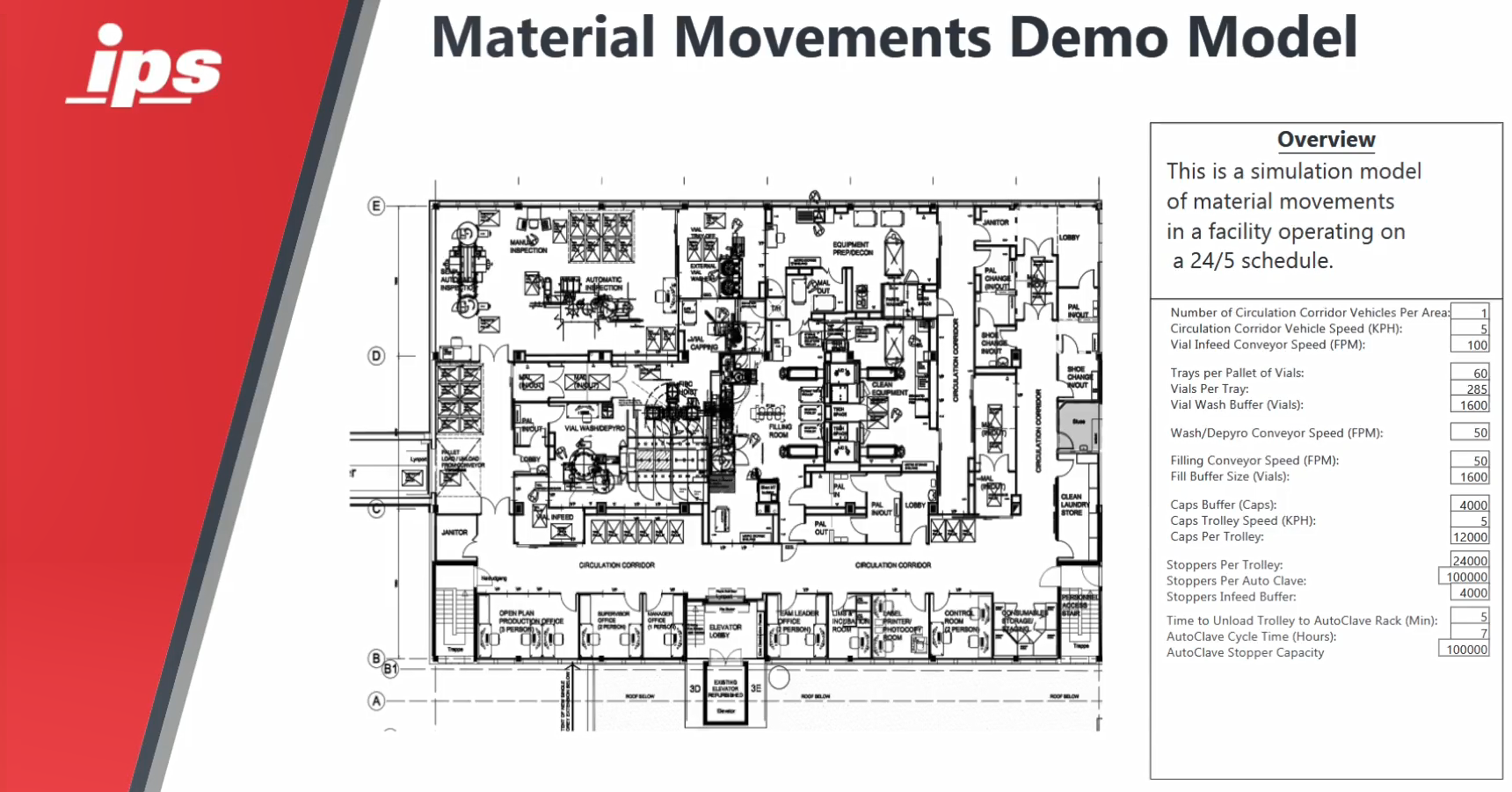

- This packaging component manufacturing facility video shows simulations of updates to the facility and its warehouse material movement.

- Watch this video for examples of material handling, and a simulation of how the manufacturing process materials are moved.

This demo video is an example of IPS-Integrated Project Services LLC resource and operational event simulation modeling in which the company showcases material movements in a dry-fill operation located on the second floor of a facility. This type of simulation is best suited for answering questions about a process with multiple conflicting or interacting elements that can be hard to predict using traditional methods.

It is rarely a question of “Can we model it?” but a question of “What solution are you looking for and what data is available.” Benefits of a simulation model include the capability to rapidly test many different “what-if” scenarios, increased comfort in results through live demonstration, the ability to account for variability in the process and having outputs tailored to specific business needs.

In this demo video, the desired result was to assist with right-sizing the pallet staging areas on the floor, determining the required number of vehicles, right-sizing the autoclaves as necessary for the sterilization of materials and confirming that a single elevator could support the required material movements to supply the area.

Some outputs captured in this demo were the use and wait times of vehicles/elevators, the number of raw materials consumed and the number of finished goods produced. This type of modeling is very customizable. Any changes can be made, including additional outputs/inputs, testing unpredictable events (elevator going down for maintenance or a vehicle out of service) and adding personnel movements.

Read the article on Plant Engineering